Tin (IV) Oxide

Tin Dioxide – White Tin Oxide – Stannic Oxide

SnO2

18282-10-5

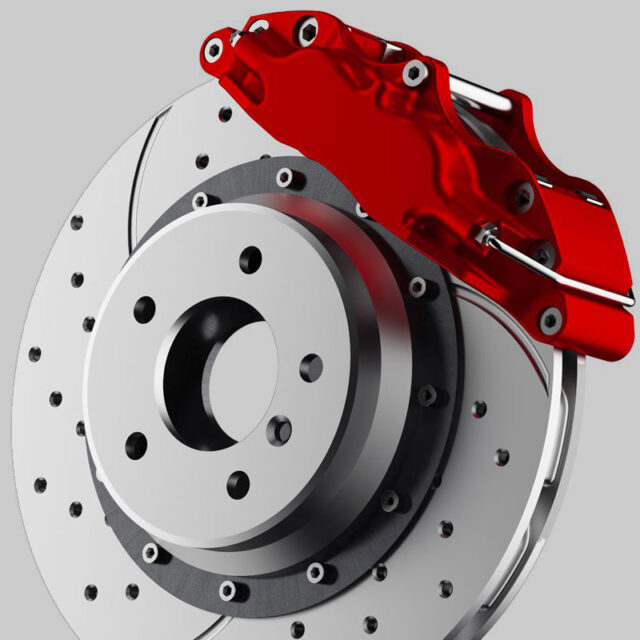

Thanks to the extreme thermal stability that distinguish Tin (IV) Oxide, it is a fundamental raw material in the production of certain pigments and ceramic glazes, technical glass, displays, automotive and marble polishes, and in recent years it has also found excellent application in the surface coating field.

![]()

Thanks to its chemical and physical characteristics, this tin oxide is mainly intended for standard ceramic use. It is especially valid in the production of ceramic dyes, while also offering effective application in the glass sector.

![]()

This type of tin oxide is mainly designed for application in the glass sector and the field of aerospace components due to guaranteeing absolute and constant physical characteristics.

![]()

This type of Tin Oxide is suitable for special ceramic pigments when larger surface areas are required, in addition to which it also finds an important niche in the Sputtering targets sector where it maintains a standard purity not exceeding 99.9%.

![]()

Since the most important characteristic of this type of tin oxide is its absolute whiteness, it is suitable for manufacturing sanitaryware, tableware and ceramic glazes. It is obtained by means of a special thermal cycle that exalts its whiteness.

![]()

This type of tin oxide is particularly suitable for special applications, such as materials for the automotive industry and the production of the highest-quality ceramic pigments, above all due to its very fine grain size.

![]()

Thanks to the special characteristics of the slightly larger dimensions and spherical shape of its particles, this type of Tin Oxide finds application when a much smoother product is required than that offered by common tin oxide.

![]()

This type of Tin Oxide is produced with painstaking care for obtaining a purity exceeding > 99.99%. It is mainly used in the Sputtering targets sector and other sectors where the highest purity is indispensable.